LIMITED SPOTS

All plans are 30% OFF for the first month! with the code WELCOME303

LIMITED SPOTS

All plans are 30% OFF for the first month! with the code WELCOME303

LIMITED SPOTS

All plans are 30% OFF for the first month! with the code WELCOME303

LIMITED SPOTS

All plans are 30% OFF for the first month! with the code WELCOME303

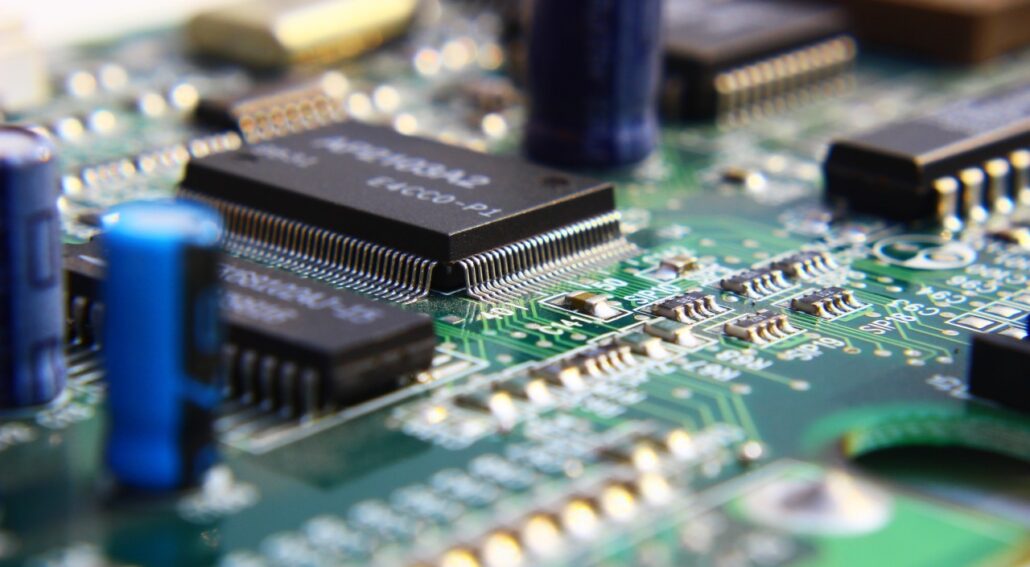

If there's anything we know about entrepreneurs, it's that they're always looking for ways to improve their businesses and cut costs. That's why so many people have started making products themselves or outsourcing them overseas in order to save money. And if you've got an original idea for a small business -- maybe even something that could be turned into a successful Kickstarter campaign -- then you may also want to consider going down this route as well.

But what happens when you decide to manufacture your product yourself rather than outsource it abroad? Can you really create a brand-new item from scratch just by assembling parts together? What are some of the challenges involved with doing so? Keep reading to learn more.

This post was originally published on Feb. 10, 2017. We updated it Aug. 22, 2021, to include information regarding 3D printing services.

One way to bring your product ideas to life is through custom manufacturing. You can purchase kits (like LEGO) that allow you to assemble items like furniture, electronics, toys and other goods. While these types of kits tend to provide good results, they don't offer the same level of quality control and customer service that a professional factory might give you.

That said, not all manufacturers require you to supply specific components for your project before production begins. Some will simply need everything needed to complete the job (which means you'll only pay for shipping). In either case, here are three things you should look for when choosing which company to work with:

A great reputation — Manufacturers often put time and effort into getting positive reviews on third party review sites. If possible, check up on any complaints that others have posted and see if they were resolved satisfactorily. Pay attention to comments left under those reviews too. Does everyone seem happy with the final product? Was the company easy to communicate with? Did they answer questions quickly and professionally?

Quality materials — When you buy a kit, you typically won't receive high-quality tools and supplies. Even if you use an experienced DIYer to build your product, he or she probably wouldn't have access to the same equipment and resources used at most factories. Make sure the kit contains enough pieces to ensure your finished product looks exactly the way you imagined it would. Also ask whether the material provides long-term durability and reliability.

Customer support — Whether you choose to source your product locally or elsewhere, you shouldn't expect to deal directly with employees who actually built it. Instead, you'll likely speak to someone else over the phone or via email. Find out what kind of response times you can count on and what kinds of problems you can anticipate dealing with. Ask about warranties, guarantees and return policies. It's important to feel confident that whatever you end up with meets your expectations.

Once you've found a reputable supplier, it's time to start planning your project. You'll first need to determine where you'd like to ship your product. Then contact the manufacturer to discuss options for producing your creation.

The average turnaround time for creating a prototype ranges anywhere between two weeks to several months depending on the complexity of the project. This depends largely upon factors such as type of product, size, design, number of units being produced and the availability of required materials. So prepare to wait patiently until you receive your final shipment.

In general, companies charge fees based on the amount of labor hours expended during assembly plus packaging/shipping expenses. However, keep in mind that prices vary widely among suppliers, so shop around carefully. Don't forget to factor in potential upgrades and add-ons. For example, adding extra features to a toy that already exists can raise its price significantly. On top of that, you may have to cover additional taxes and duties based on the value of the product itself.

Keep in mind that while ordering samples is common practice, it isn't necessarily necessary to obtain these early on. Many suppliers plan projects ahead of time and send sample orders later after receiving payment because they aren't able to guarantee delivery dates until then. By waiting until the last minute, you can avoid paying extra for expedited shipping and potentially save valuable time.

Another thing to consider is whether or not you prefer working with smaller orders. Most large corporations tend to handle larger ones better since they have greater capacity to accommodate them, but many small manufacturers may struggle to fill orders less than $1,000 unless they expand their operations or partner with another company.

You now know how to go about sourcing a manufacturer for your product, but you still haven't answered our initial question. How much does it cost to produce a product? Well, unfortunately, the numbers fluctuate wildly according to demand, available technology and market competition. But generally speaking, you can expect to spend somewhere between 50 cents per unit to several dollars per unit.

Of course, that doesn't mean you won't come across inexpensive opportunities. A lot goes into mass production, including research and development, marketing, distribution channels and overhead. As a result, certain industries tend to carry higher markups due to increased risk. This includes food & beverage, health care and medical devices.

However, for comparison purposes, let's say that you want to produce 100 widgets in total. With a markup rate of 70 percent, you'd have to spend roughly $7 each widget in order to earn back your investment. Of course, it varies considerably depending upon industry standards and your chosen model. In addition, you may encounter unexpected delays along the line, so it's best to budget accordingly.

As mentioned earlier, different producers use varying methods to figure out the true costs associated with your product. These calculations usually involve estimating variable costs such as labor, raw materials, packaging and transportation. Other fixed costs such as rent, utilities and insurance may also apply.

To help estimate these figures, you can try using software packages designed specifically to aid in this process. One popular tool, called CostEstimatePro, takes a user inputted description of a project and calculates estimated overall costs. Another option is MS Excel, which allows users to automatically generate charts showing the breakdown of various costs.

So yes, it's definitely possible to manufacture your own product. Just remember that there's no "one-size fits all" approach, so take your time and weigh every decision carefully. Happy shopping!

In today's world, it seems like there are more options than ever when it comes to where we shop and what we consume. We can now choose between purchasing goods through Amazon or eBay, as well as local stores such as Target or Walmart. But did you know that there are also many companies out there who produce their products themselves? They're called "manufacturers" — they don't just make things in factories (though some still do), but instead create unique items using various materials and techniques. These types of businesses have been around since before America was even founded.

But with so much competition on the market these days, manufacturing has become increasingly difficult. Not only does this mean higher prices for customers, but also lower profit margins. It requires more time and resources to create something new, especially if it involves creating a prototype by hand. And yet, not every entrepreneur gives up on his/her dream because of all those factors. In fact, thousands upon thousands of people across the United States have taken part in starting their very own business, whether it be selling homemade crafts, making clothing, building furniture, etc.

So if you've got an entrepreneurial spirit inside of you, here are some tips on how to start your own manufacturing company.

Yes! If you want to get started making your own product, first consider which type of item you'd like to build. Some products lend themselves better to mass production while others require more customization. For example, let's say you were thinking about starting your own custom-made jewelry line. You could purchase wholesale gemstones from a reputable dealer and then work with them to design each piece individually. However, there are other methods to take advantage of modern technology.

You can search online for suppliers who will allow you to place orders via email or phone call. Just Google "wholesale supplier," along with whatever specific item you need. This way, you'll be able to track shipments and receive updates as soon as your package arrives at its destination. As long as you pay attention to details, shipping times should always remain relatively fast.

Once you send off your request, keep tabs on the status of your shipment until you receive confirmation that it arrived safely at your doorstep.

It may seem easier to go straight to the manufacturer and ask them to ship your item to buyers. While this might save money over time, it doesn't provide the same kind of customer service. Also, if you decide to use this method, remember that most manufacturers won't accept returns unless you bought defective merchandise. So be sure to read the terms and conditions thoroughly before placing any orders.

If you're looking to turn your handmade ideas into reality, try contacting several different manufacturers and see which ones best suit your needs. Ask questions regarding quality control standards, delivery policies, payment processing procedures, and return guidelines. Make sure to check reviews left by past clients, too. With access to hundreds—if not thousands—of websites offering information on everything from fashion brands to household cleaners, choosing the right manufacturer shouldn't prove to be hard at all.

Buying direct from the manufacturer is beneficial for everyone involved: the buyer gets great deals and faster shipping without having to wait weeks for packages to arrive, and the manufacturer saves money on packaging supplies and labor costs. Plus, sellers benefit from higher profits due to reduced overhead expenses.

However, if you plan on running your own business, you must understand that buying direct means taking responsibility for inventory management, sales tracking, and customer support yourself. That being said, many manufacturers offer services specifically designed to help small entrepreneurs manage their businesses. One option is eCommerce platforms, which connect buyers with retailers. Another alternative is outsourcing your entire operation to freelancers, allowing you free time to focus on marketing and growth strategies. Whichever path you choose, make sure to set realistic expectations and goals for success.

There are two main ways to approach manufacturers: either cold calling or networking. Cold calling is pretty straightforward, though it takes time and patience. First, research potential manufacturers based on your target audience and desired niche. Then write down possible leads, including addresses and website URLs, and follow up accordingly. To maximize efficiency, you can group similar industries together under separate categories.

For example, if you wanted to reach makers of baby toys, list names and numbers of toy companies under “toys.” Next, select a few contacts within each industry and begin reaching out to them personally. Letting someone know exactly what you intend to sell can give your pitch extra credibility, as well as speed up response times. Once you land a conversation, try asking for advice on improving your product or requesting samples to test in person.

Networking can be done in less formal environments and typically includes attending events, joining groups on social media, and interacting with fellow creators on forums. Networking can open doors quicker than cold calls alone, but is also dependent on personal connections. Try approaching people whom you already know or whose fields overlap yours. When networking, think outside the box by asking friends and family members for recommendations. Even if they aren't interested in your product, chances are they know someone else who would love to hear about your offerings.

While both approaches have pros and cons, the choice ultimately depends on your individual situation. Keep in mind that manufacturers tend to prefer working with larger organizations rather than individuals. Therefore, if you don't have enough capital to invest in branding or advertising, look elsewhere.

Although it sounds counterintuitive, yes, it is possible to sell directly to consumers. There are plenty of sites where users can browse listings and find products offered by independent sellers. Many of these sites function similarly to Craigslist, connecting buyers with sellers. Additionally, third parties often facilitate transactions between the seller and consumer, acting as middlemen and taking a cut of the sale price.

The benefits of doing business this way include no minimum orders needed to stay afloat, no risk of getting scammed, and the ability to negotiate pricing. On top of that, it allows you to scale up slowly and easily add additional items to your catalog without needing to worry about storage space or stock levels. Although it can feel impersonal, shopping for physical products online isn't inherently bad. After all, this process works perfectly fine for millions of shoppers worldwide.

Whether you opt to deal face-to-face or conduct business remotely, setting clear boundaries early on can prevent misunderstandings later on. Before finalizing your plans, determine how frequently you expect to communicate with your partners and establish rules for dealing with refunds and cancellations. Be upfront about your intentions to avoid future conflicts and maintain trust among all parties involved.

And after all, there's nothing wrong with giving back to society. In fact, supporting grassroots movements that promote equality and sustainability can lead to greater profits overall.

I was in the middle of writing this article when Amazon announced it would no longer be taking orders on anything but its own devices, including Kindle e-readers.

It's not that these gadgets are bad — they're very good — but there have been so many recalls over faulty batteries, what if mine also stops working? What happens then?!

In short, my fear was realized. And with it came the realization that even though we live in a world where technology can make our lives easier than ever before, inventors still need help creating their ideas into actual physical items people can buy and use. We've written about why this is important earlier too.

So, while I'm excited by all the possibilities of 3D printing (and will probably end up trying out some DIY projects) until something like Amazon comes along again, we'll always need manufacturers. But how does someone go about finding one? In other words, how can anyone start manufacturing their own product? Let me explain.

Before going any further, let's take a look at how exactly a product moves from being just an idea on paper to actually existing as a tangible thing you can pick up off a shelf or click through to purchase online. To see the entire process from beginning to end, check out How Products Become Popular.

Here's a quick overview:

You come up with an idea for a product. It might be a better way to store eggs, a unique type of shoe, or a more efficient way to cook food. You want to create it because you think people will love it.

You research whether others have created similar things already and try to figure out if yours stands apart enough to become popular. If there aren't any competitors yet, you decide to move forward anyway.

Your prototype looks promising. Now it's time to develop your design into a final production model. This involves making changes based on feedback, testing prototypes to ensure everything works correctly, and adjusting the design accordingly.

Once everything has been perfected, you send samples of your creation to different companies who may produce them for sale. Some companies will give you money upfront, others, such as Kickstarter, ask you to pay once the item starts selling well. Whichever route you choose, you now have real customers interested in buying your idea.

Now, here's where the tricky part begins. Once you receive positive feedback from potential buyers, you need those same consumers to turn into full-fledged customers willing to spend money every month so you don't run out of cash flow. That means convincing them to open their wallets each month and hand over hard earned dollars via credit card.

If you're lucky, you'll hit upon something everyone loves and can easily replicate, otherwise you'll need to work extra hard to convince people your idea is worth investing in. Remember, although most of us enjoy paying taxes and using public transportation, a lot of people simply won't care as long as they can afford their favorite gadget or pair of shoes. So it takes a special kind of person to successfully turn an inventor's dream into reality.

One last note: Although getting a product manufactured seems pretty straightforward, the journey isn't perfect either. There are lots of bumps along the road, delays, and unexpected costs, which is why we often talk about "manufacturing" rather than "making." For example, during development, maybe you discover that the materials used to build your device are super expensive and impractical. Or perhaps you realize it's harder than expected to mass produce your creation, meaning it'd cost less per unit to license it instead of producing it yourself.

Finally, remember that having a successful venture doesn't guarantee riches overnight. As writer John Rampton points out, it took years for Tesla to finally succeed after dreaming up his revolutionary AC induction motor, and he had to wait another decade for it to gain traction outside of specialty electronics stores. Not only that, even today's top inventors haven't necessarily found success right away, despite coming up with groundbreaking innovations. Apple cofounder Steve Jobs passed away recently, for instance. He started Apple back in 1976, but didn't launch the iPhone until 2007. Another notable tech entrepreneur, Michael Bloomberg, launched AirNew York in 1999, but sold it in 2014.

So keep that in mind as you read on. Next, let's talk about ways to bring your product to life.

Although manufacturing products sounds easy enough, the truth is that doing it alone is extremely difficult. Most inventors rely on various types of consultants to guide them throughout the process, ranging from engineers to lawyers. These experts are necessary since inventing requires specialized knowledge, skills, equipment, and resources that most people lack access to.

The first step is deciding how much money you intend to invest in bringing your project to market. Are you looking to save money early on, or are you hoping to recoup investment quickly? Either option brings advantages and disadvantages. For example, saving money could mean spending less overall, but you won't know unless you test your idea thoroughly. On the flip side, spending more upfront gives you the opportunity to fine tune your concept, but you risk wasting money if you miss critical details.

Next, identify where you fall within this spectrum. Do you prefer to start small, hire contractors, or partner directly with big corporations? Will you approach investors for funding, seek licensing agreements, or opt for crowd-funding platforms? Depending on your goals, you should consider which options best suit your needs.

Then determine what sort of relationship you'd like to maintain with your manufacturer. Would you like to collaborate closely with a single vendor, or would you prefer multiple vendors? Maybe you plan to release several versions of your product simultaneously, requiring separate processes for distribution. Do you want to retain rights to future updates, modify your product, or sublicense it outright? Each decision affects the amount of control you exercise and the level of support you expect from your chosen company.

Manufacturers range from large enterprises offering services to smaller businesses focused solely on sales. When selecting one, understand what role you feel comfortable filling in relation to logistics, marketing, engineering, quality assurance, etc. Don't assume your choice automatically makes sense, especially given that most business relationships evolve naturally over time as parties learn more about each other. Take advantage of opportunities to meet reps face-to-face, chat on the phone, or email directly to get a deeper understanding of their capabilities and limitations.

There are two main methods of building products. One method is referred to as "mass production," where machines assemble individual units according to preprogrammed instructions. The second method is called "selective assembly," where workers select parts individually and put together components without precise specifications. Selective assembly generally produces higher quality pieces, but also results in fewer finished goods.

Depending on your preferences, you should weigh both approaches against one another. Mass production typically offers greater efficiency and lower overhead expenses, whereas selective assembly provides superior craftsmanship but increases labor costs.

To speed up production, you can employ dedicated factories or contract providers. A dedicated facility usually operates 24/7, giving you peace of mind knowing your shipment is safe while waiting for delivery. However, hiring outside specialists allows you to focus more energy elsewhere and delegate responsibilities.

When choosing between outsourcing or self-employment, consider factors like location, experience, training, expertise, scale, communication, and flexibility. For starters, do you possess technical skills required to manage complex machinery or supervise employees? Can you speak English fluently? Does your country require a specific visa status? Is there room to negotiate prices? Also consider whether you want to remain flexible in case of fluctuations, or commit to a fixed monthly budget.

A third alternative is partnering directly with suppliers. While this saves time, it limits your ability to influence pricing decisions. Plus, dealing directly with vendors exposes you to risks associated with shoddy workmanship and poor customer service.

Lastly, think about what you envision your product eventually becoming. Is it a niche product that appeals mostly to hobbyists, or would it appeal to mainstream audiences? Your answer determines what kind of factory suits it best.

Many entrepreneurs opt for custom shops due to high demand, but that's not always feasible. For example, if you're planning to sell T-shirts featuring your logo, it wouldn't make sense to order 50 dozen to fulfill bulk requests, since shirts rarely sell in quantity that large. Instead, stick to standard sizes and shop around for retailers who offer larger quantities.

Finding a manufacturer suitable for your product depends largely on your target audience, size and scope of operation, available funds, and desired profit margins. After weighing each factor, narrow down your list to three to five viable candidates. Then compare notes with each candidate to gauge compatibility. Ask questions related to their strengths and weaknesses, and request references from previous clients. Be sure to inquire about turnaround times, shipping fees, payment terms, warranties, intellectual property concerns, and return policies. Finally, schedule meetings with representatives and conduct thorough interviews.